The measurement data indicates whether squeegee forces and printing speed are consistently maintained. Deviations indicate wear, incorrect settings, or process instabilities, providing a clear basis for optimization measures.

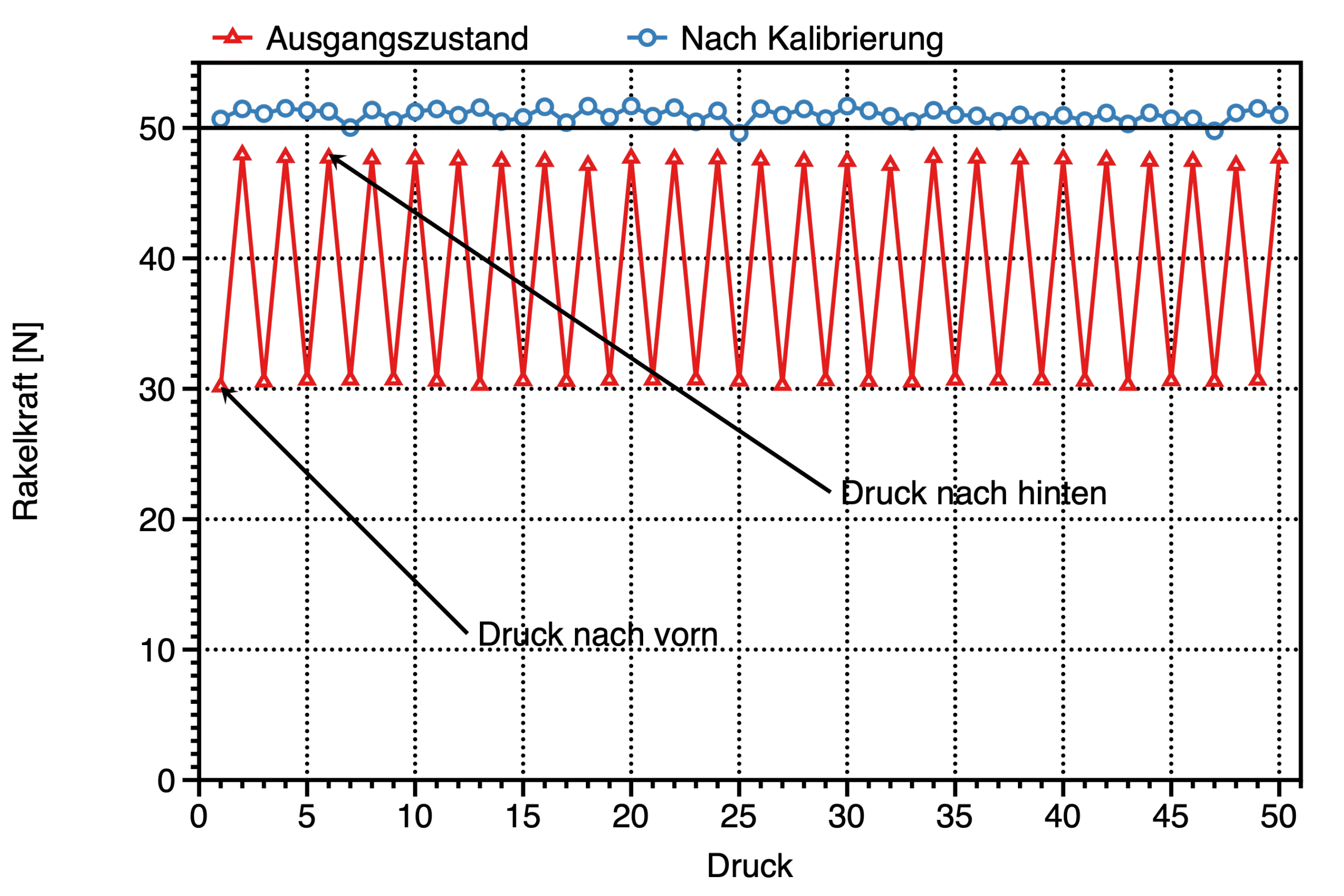

Front Drift Measurement

This chart shows the change in squeegee force over time as the squeegee moves from front to back (Front). The goal is to identify deviations from the target force, which may indicate mechanical influences, wear, or inconsistent force settings.

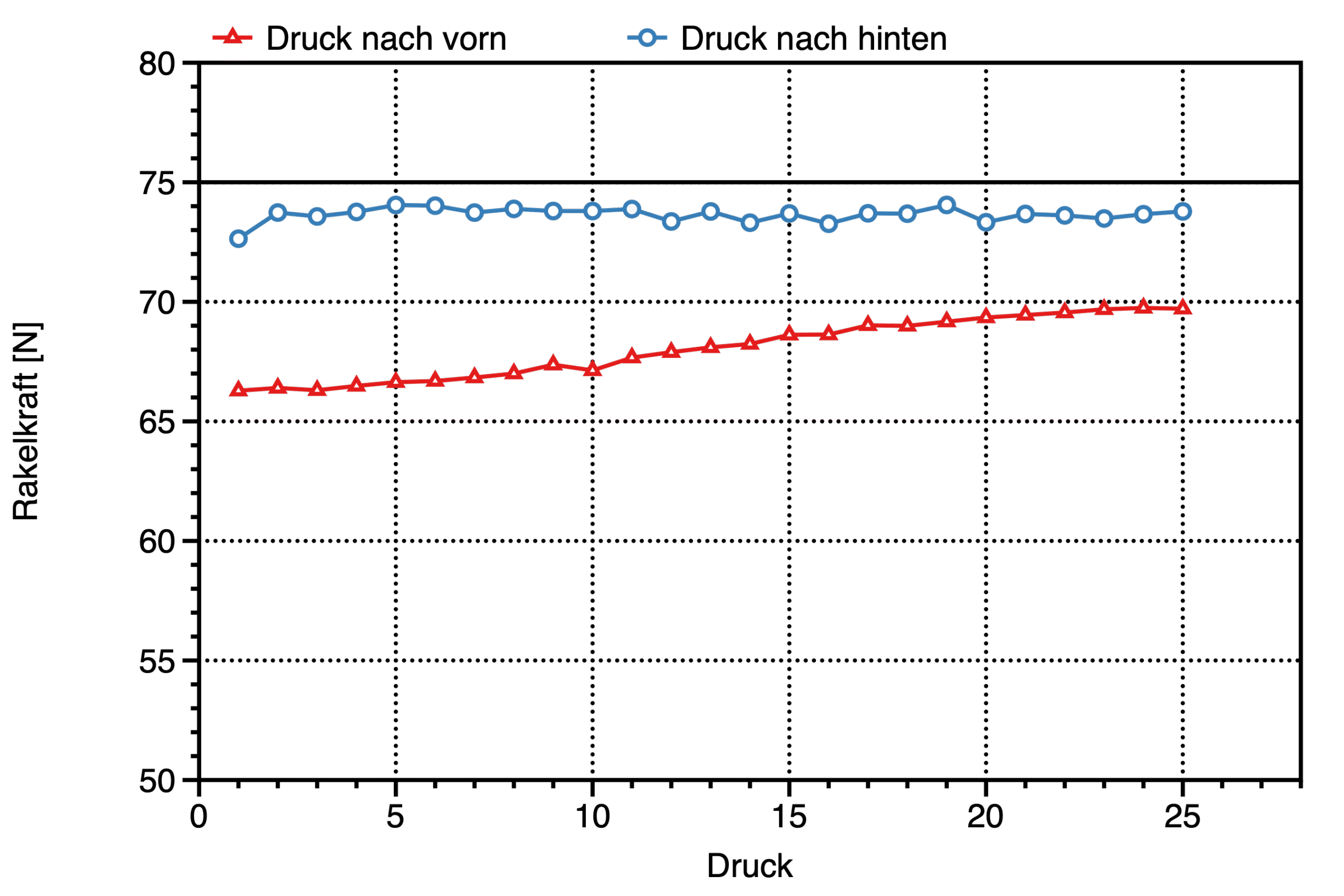

Front / Rear Comparison

Here, the measurement results for both squeegee directions (Front and Rear) are compared. A consistent force in both directions is crucial to ensure consistent paste printing and reproducible printing results. Deviations indicate possible mechanical or pneumatic problems in the printing system.

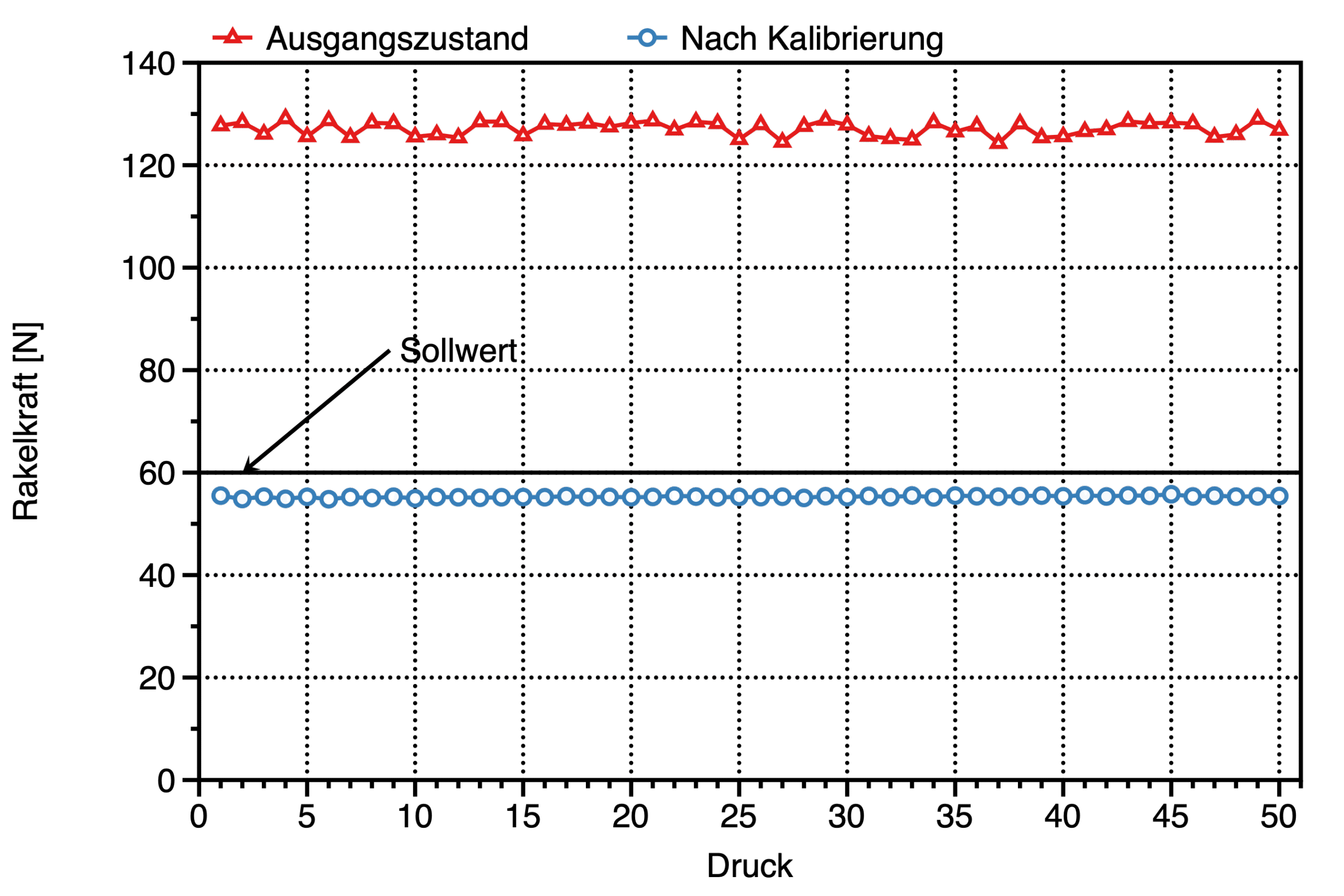

Nominal Force Measurement

This chart compares the measured force with the set target force. The aim is to ensure that the machine maintains the desired printing force precisely and stably throughout the entire printing cycle. Deviations may indicate calibration errors or uneven wear.

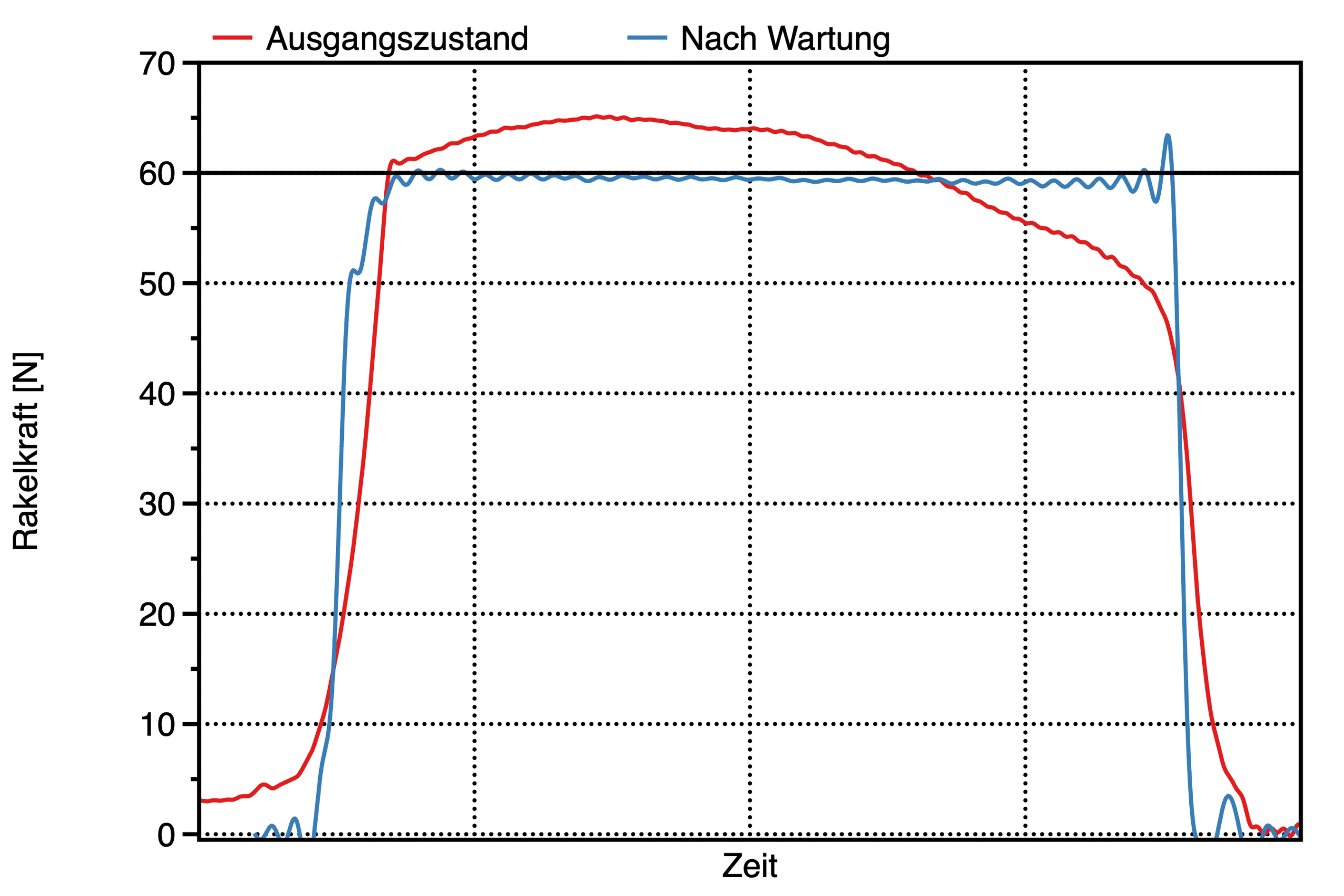

Flat / Round Squeegee Comparison

Here, the force distribution between a flat and a round squeegee is shown. The analysis helps to understand how the squeegee geometry affects the printing process, e.g. in terms of uniform force transmission and the service life of the squeegee.

Leave A Comment