The results show deviations in the X, Y, and Theta directions, as well as the stability of the printing process. In addition, squeegee forces are recorded over the entire printing stroke. Deviations indicate instabilities, incorrect settings, or maintenance requirements and provide a precise basis for process optimizations.

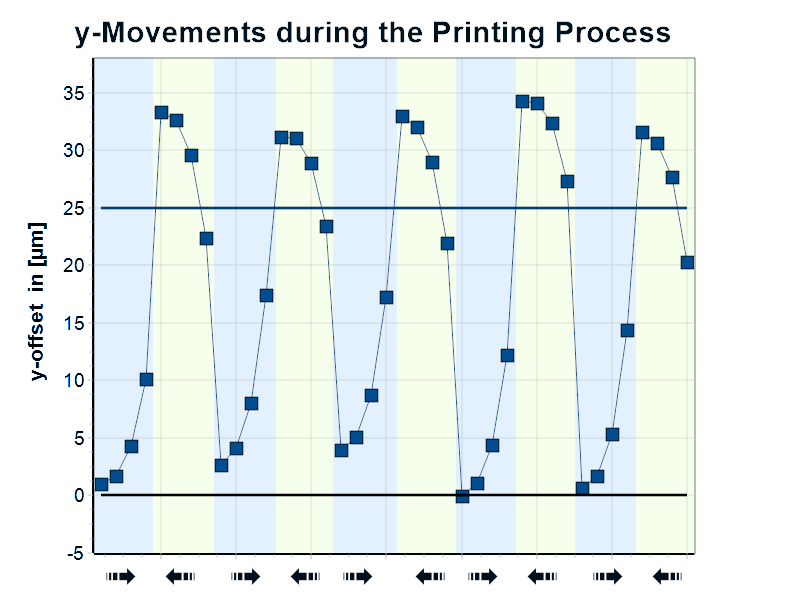

Position and motion measurement

Determines the positional changes of the squeegee with high resolution during the printing process. Deviations or instabilities in the printing movement become visible.

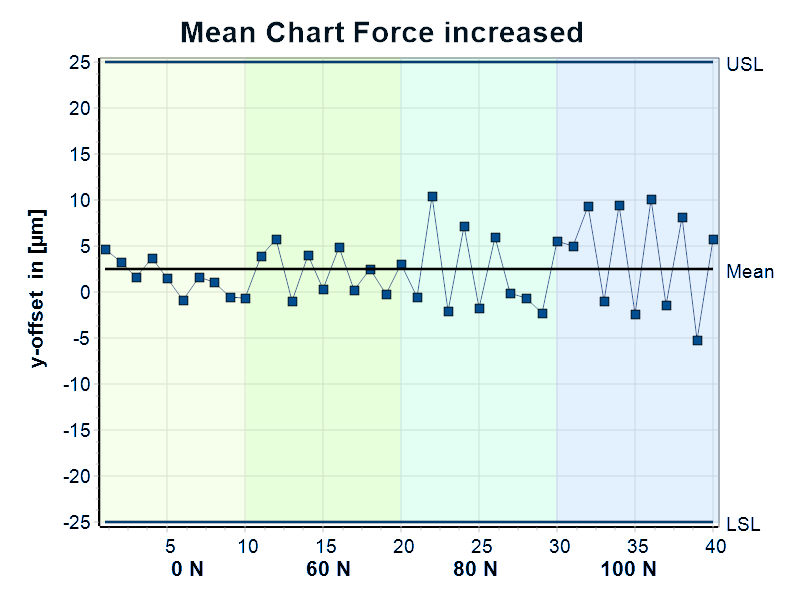

Force measurement – Good printer

Measures exactly the forces occurring during printing with increasing load, here using the example of a well-adjusted printer.

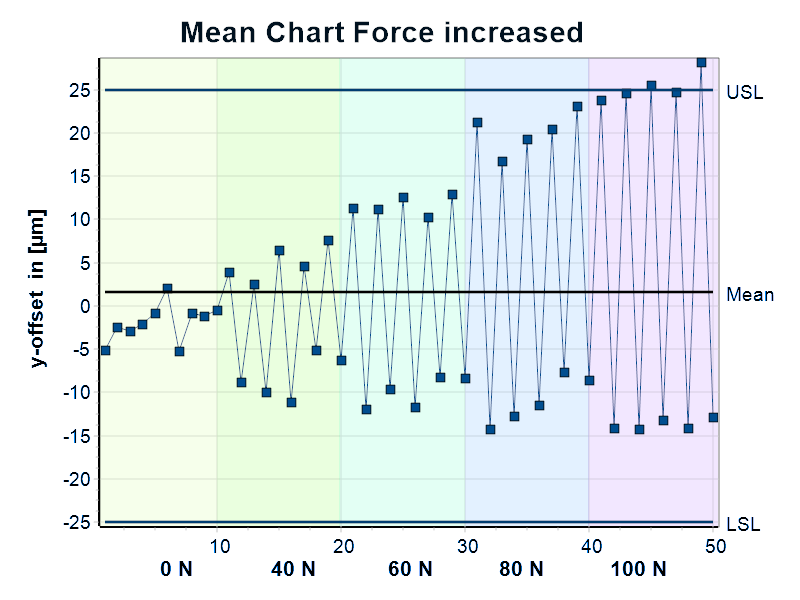

Force measurement – Bad printer

Comparison under the same conditions with an incorrectly adjusted printer to make mechanical problems or incorrect calibration visible.

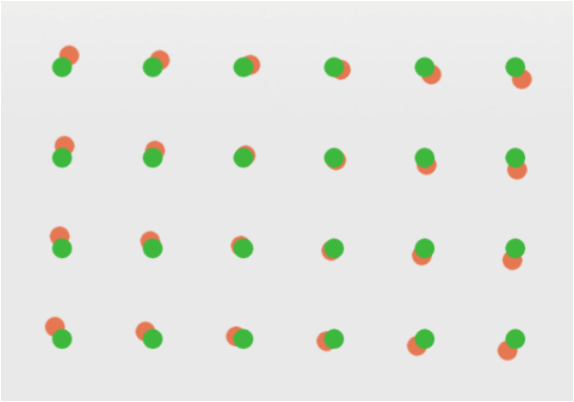

Theta offset (angle deviation)

Analyzes the offset between the printed and the actual target points (rotation / inclination) in the entire printing field.

Leave A Comment